The Embodied Carbon in Construction Calculator (EC3) tool methodology takes several bold steps to use what program operators, LCA providers and manufacturers have worked very hard to produce. Product category rules (PCRs) using different parameters to define product categories or groups; inconsistent content and data in an environmental product declaration (EPD), and PDF delivery in non-standardized layouts all make it very complicated to machine read and digitize to put today’s available data to use. Notwithstanding, this methodology delivers, for the first time, a scalable way to compare a single product’s embodied carbon impacts to all other similar products in a category.

Today’s environmental impact reporting system can no longer meet the needs of today’s environmental impact reporting requirements. People need understandable, meaningful and actionable information to make decisions. With the increasing awareness in the building and construction industry that new construction is accelerating climate change, and that embodied carbon (the global warming gasses from energy consumption and chemical reactions in the manufacture, transport and installation of construction materials) presents the greatest near-term threat, the need for new and powerful decision-making tools is urgent. That said, the tools are only as good as the underlying data, and therein lies the rub.

Even though there are now more than 2,300 ISO 14025 Type III environmental declarations (EPD is the colloquial term) for building products publicly available on North American program operator web sites (not counting the many thousands of on-demand ones not on a program operator’s site—mostly for concrete), from 700+ building product manufacturers in North America, representing an exponentially greater number of products, today’s EPD reporting system and processes are not effectively delivering understandable, meaningful and actionable information to make decisions.

Program operators (PO) – Using the same ISO 14025 standard, each creates PCRs and EPDs their own way.

Product category rules (PCRs) and EPDs – Not only are they different from each PO, there can be significant differences between documents in a single program.

EPD design and delivery – Every program operator has a different layout and length. Documents are still delivered in PDFs making the content unavailable for other uses. Certain program operators even see their EPDs as their copyrighted content. Making it freely available for other uses doesn’t fit their business model.

Content included in EPDs – Because the people involved in making EPDs have always been technical people, it’s no surprise the result is a lengthy technical document. At Sustainable Minds we like to ask, “if an EPD is a report of a (LCA) report, then why is it still so long?” They are not written or designed for either non-technical users (like an architect, engineer, contractor, owner [AECOs]) or machines to read and digitize.

Costs will need to come way down for more manufacturers to create EPDs, particularly now that there is demand for more specific one-product, one-manufacturer, one-facility EPDs. This new requirement will result in making EPDs even more useful.

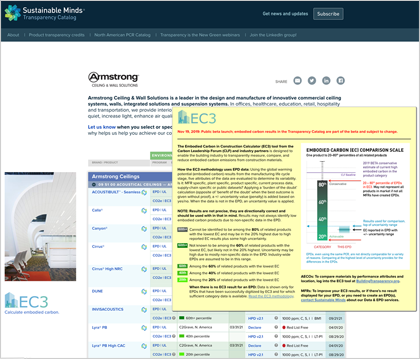

EPDs, even when created from the same PCR, are not directly comparable for a variety of reasons. By bypassing most of the conventionally required comparison criteria and applying a conservative calculation to account for lack of specificity in the data, comparing a manufacturer’s EPD at the highest level of uncertainty to the industry range provides for a conservative estimate of the differences in the EPDs. This methodology delivers a scalable way to compare a single product’s embodied carbon impacts to all other similar products in a category.

The EC3 tool methodology uses the global warming potential (embodied carbon) results from the manufacturing life cycle stage and evaluates five attributes of the data are evaluated to determine its variability. Is the EPD:

Applying a ‘burden of the doubt’ calculation (opposite of ‘benefit of the doubt’ when the best outcome is given without proof), a +/- uncertainty value (penalty) is added based on yes/no. When the data is not in the EPD, an uncertainty value is applied. A category range highlighting the 20–80th percentiles is calculated to identify the achievable to conservative embodied carbon results. 60% of the products in the category (from manufacturers who have created EPDs) are in that range, 20% are lower and 20% are higher. This enables users to consider their own EC goals when selecting and specifying products.

What you should remember about the results

It’s a ‘stick’ approach for sure, but often this is what it takes to get people to move. These reporting requirements may sound straightforward, but producing that data requires even greater investment from manufacturers. Some may even say it’s a burden and are unable to report at that level due to cost, time and competitive / proprietary reasons. These reasons are all valid, but this is a start of a longer journey with the roadmap to be defined.

If the building and construction industry really will care about dramatically reducing the embodied carbon in buildings, and if the goal is to create understandable, meaningful and actionable EPDs for AECOs and machines to use, then the EC3 tool methodology will drive the following changes:

The E3 tool, in its first beta release, is big and bold and has required many, many people to come together and share conflicting ideas and intents. Kudos to the EC3 core team: Kate Simonen, Stacy Smedley and Phil Northcott for being so bold and moving forward with the mindset of not letting perfection get in the way of progress and engaging the community to ensure it continually improves! They are asking manufacturers, LCA practitioners and building industry professionals to help provide input and shape data and methods to build an embodied carbon data ecosystem that economically drives towards higher quality data and tools to enable meaningful interpretation. Join the discussion.

Sign up for an EC3 tool account @ BuildingTransparency.org [2]

For information on the EC3 tool methodology and to support the methodology development visit

CarbonLeadershipForum.org/projects/ec3/ [3]

Tooltip with methodology explanation and key accompanies each result for handy reference. Click the CO2e | EC3 [6] link to go directly to the EPD page in the EC3 tool to compare products within the category or to start modeling a project.

Find all EPDs from a manufacturer with the EC3 tool result which links directly to the EC3 tool to enable comparisons within the category or to start modeling a project. In the EC3 tool, manufacturer and EPD pages link to their listing in the Transparency Catalog for product and contact information to connect the last mile and help get the product into the specification.

Manufacturers: SM has introduced affordably priced, simpler and standardized product & facility-specific EPDs to improve EC results in the EC3 tool and for Buy Clean CA Act awarding authorities. Delivered in the cloud, into the EC3 tool and in PDF, these EPDs are for manufacturers who:

Links:

[1] http://www.sustainableminds.com/files/images/blog/20191119_intro2_0.png

[2] https://www.buildingtransparency.org/en/

[3] http://www.carbonleadershipforum.org/projects/ec3/

[4] http://www.transparencycatalog.com/

[5] http://www.buildingtransparency.org/

[6] https://buildingtransparency.org/dashboard/epds/c15e9d191fbc4a2880be961c464f3068

[7] http://www.sustainableminds.com/contact-us